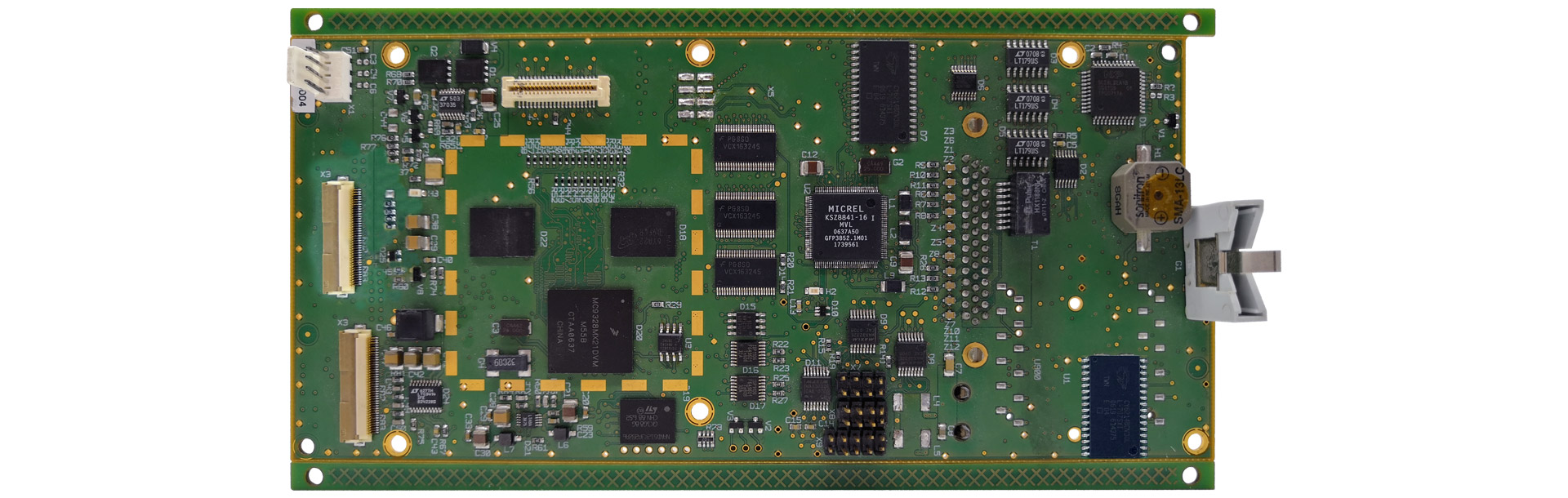

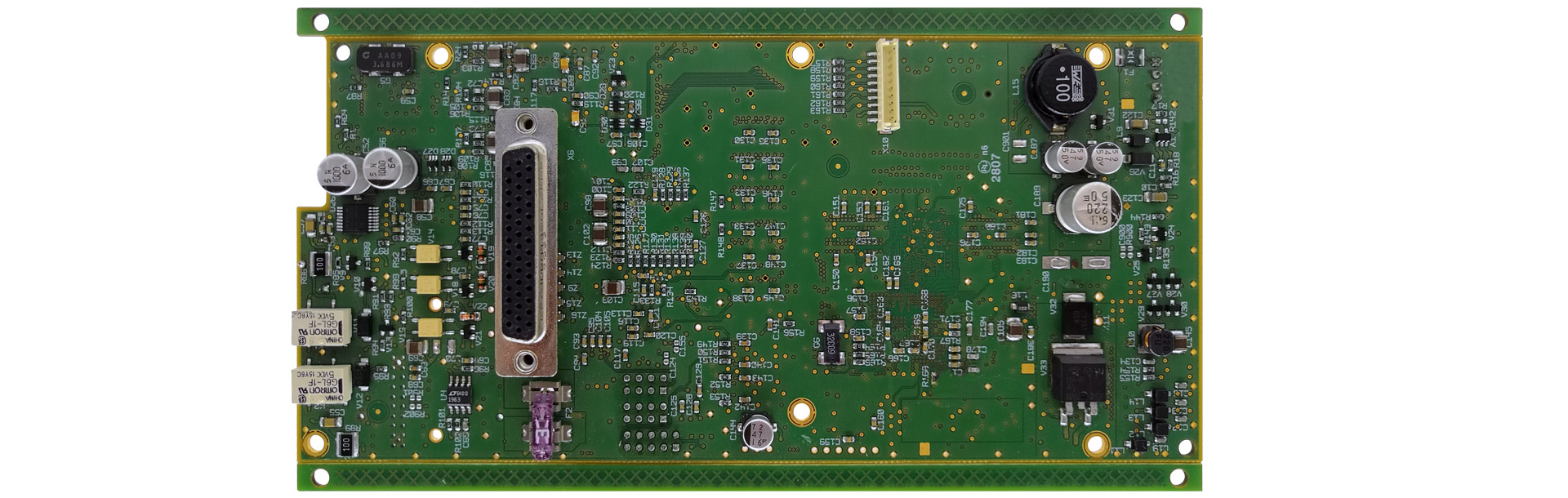

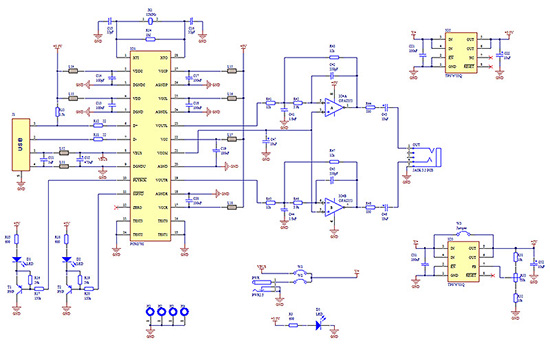

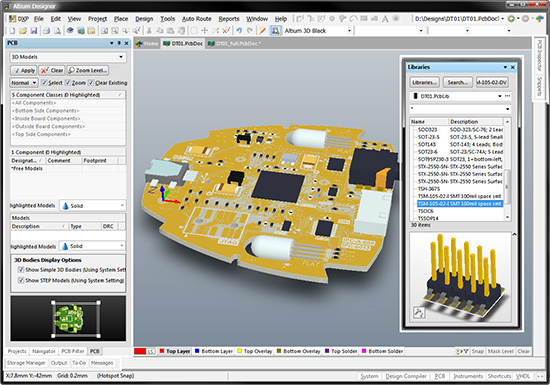

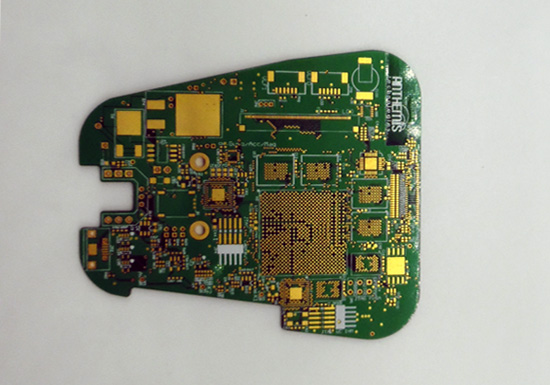

During electronic CAO subcontracting, we follow a rigorous process for the study and electronic routing of your card. At each key stage, our team of implanters validates the work with you: diagrams, placement, routing, DRC, adapted impedance and HDI, manufacturing and assembly file.

Phases of electronic CAO subcontracting

Based on your data and technical specifications, we will set up a rigorous and quality PCB CAD design process. Our electronic CAO stations allow us to import netlists from other CAD software such as: Altium Designer, Cadstar, Eagle, Cadence, Visula, Orcad, etc.

PCB design process

NEED A CAD PCB STUDY?